The biggest benefit of using laser cutting is the efficiency and quick results with uncompromised preciseness. These modern machines can even cut or engrave highly intricate designs in less time as compared to the traditional methods.

But are you getting the maximum efficiency from your laser? Well, maybe not! Here are six tips from experts that will help you maximise laser production.

Adjusting the Resolution a Little can Fetch Significant Results.

Modifying the resolution can help you get better throughput, and it’s easy as well. DPI or Dot per inch has a significant effect on the image’s clarity. The closer the dots will be, the higher the quality will be.

Furthermore, lowering the resolution helps in decreasing the turnaround time, so you need to operate the laser for less time, which saves power.

Ensure using the blur patterns when operating the machine on a low resolution to get excellent results.

Engrave Multiple Items in One Batch

Engraving multiple items in a batch can reduce the overall production time. For bigger projects that require you to print similar items in large quantities, this tip works the best.

As an example, engraving on coasters is a task you can do in batch, and it will enhance the laser’s production efficiency.

As per the experts, engraving batches can save you up to 37% time, which can be invested in printing another batch, and thus you’ll get the best results from the laser.

Use Pre-Engraved Items

Using pre-engraved items can cut the turnaround time in half. You don’t have to spend a lot of time as there’s no need to start from scratch. It would be great to order pre-engraved items from a laser engraving agency in Sydney.

These agencies can take care of the intricate design part, and you can give the final touches to the laser engraved item with minimal hassles.

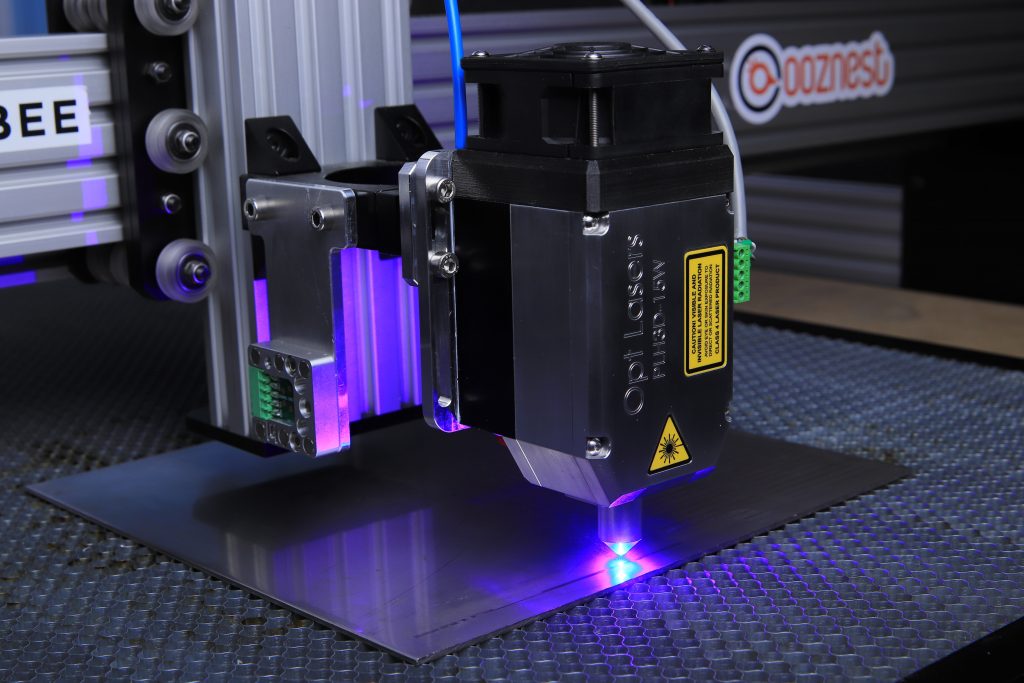

Invest in Good Equipment

Laser cutting machines can be pretty expensive, but it is paramount to invest in quality equipment. The machines manufactured by renowned brands have better hardware, and it improves production.

As per several experts, if you aren’t looking to invest in a costly machine, consider hiring a laser cutting company. These companies can do the job using cutting-edge technology, and you can get the job done without breaking the bank.

Use Colour Mapping Technique

The colour mapping technique is a real time-saviour. The technique helps the laser cutter/engraver identify the exact pattern you are looking to print but in much less time.

Furthermore, using this approach can cut down the turnaround time in half, and that’s how you can enhance the laser’s production. Use good software for colour mapping, and then feed it to the laser cutter for better cutting/engraving.

Consider Center Engraving

Center engraving works well for custom jobs such as engraving on items like coasters, awards, and more. There are several benefits of using centre engraving as it eliminates the need of creating several templates.

One template can be used to engrave on several objects. This is another proven method that enhances the laser’s production.

Final Thoughts

With these six tips, you can reduce the turnaround time while improving laser production for maximum profit. Smart businesses in Sydney outsource the laser cutting and engraving to laser cutting companies, as it’s relatively cheaper than getting a laser cutter and using it.

At Pro Laser Cutting, we can handle any type of job with any type of design intricacy. Get in touch with us, and get laser cutting and engraving services at reasonable rates. You can even order pre-engraved items with us.